What is a Production Schedule, and How Can You Make One

A production schedule is a very helpful project management tool for businesses to organize the planning, sourcing, and production process. It ensures that products reach the market efficiently and on time.

This guide will teach you how to make an efficient production schedule and all its methods and stages. Also, we will describe all the elements of the master production schedule to help you understand how this tool can improve your business' performance (with some templates to ease your work).

What is Production Scheduling

A master production schedule lists all the products in the manufacturing process, including when and where they'll be made. It includes all the materials, from raw materials to logistics.

It also incorporates many of the production processes designed to run smoothly while helping project managers spot potential issues and stop them before they can scale bigger. Production schedules are flexible and changeable project management tools that you will need to update and check regularly.

A production schedule works as a line of communication between sales teams and production. The sales team will inform the manufacturing team about the levels of demand. Then, the manufacturers will tell sales when the product will be ready.

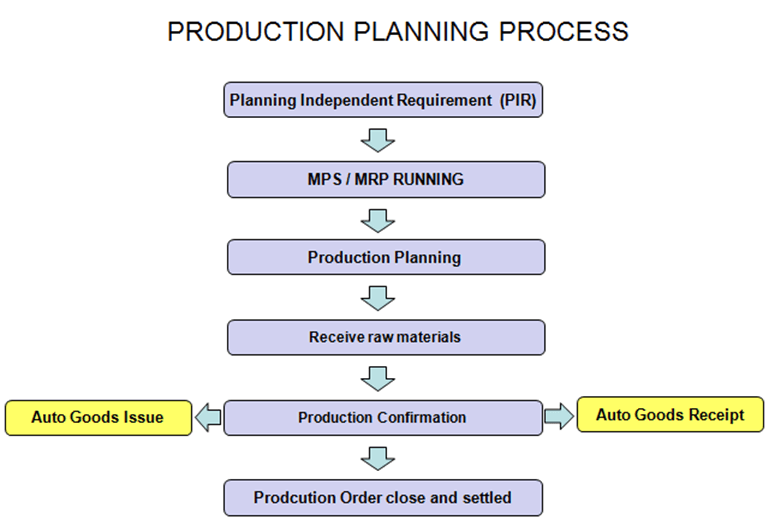

Production Planning

Production planning is balancing the supply chain and demand in a relatively long time frame. It's about deciding when to produce your own goods so customers can be served on time, building a realistic capacity plan, and bringing up a list of the materials needed for the procurement team.

A production plan will ensure that the business can develop, manufacture, and complete work orders efficiently within predefined time frames. It involves deciding:

- The quantities and types of products required to be produced for a given time period.

- The time frame that production needs to occur in.

- Raw materials and workstations needed.

In a way, a production (or master) schedule can be viewed as a tactical implementation of the strategic objectives set by the production plan.

Why Should I Make a Production Schedule

A production schedule is vital for optimizing manufacturing processes and ensuring maximum efficiency while minimizing delays, potential interruptions, or unnecessary wastage. By using production scheduling, businesses can allocate resources efficiently within a given time frame.

Some of the key points that production scheduling helps to achieve are:

- Optimal distribution of inputs, raw materials, and spare parts: Planning for optimal distribution will help bring unexpected bottlenecks to a bare minimum.

- Balance stock levels: It will help to ensure that the production facility, distribution centers, and warehouses have the proper inventory levels, avoiding stock-outs as well as excessive standing inventory.

- Even labor distribution: This will include working hours, overtime, and the number of workers per shift in the production schedule, allowing you to meet customer demand more precisely. And when demand decreases, excess staff can be assigned to other tasks.

- Optimize equipment performance: Production scheduling will reveal critical bottlenecks that help to iron out inefficiencies in equipment utilization and performance. It will enable better resource allocation and production capacity utilization, often eliminating the need to install additional equipment.

- The balance between product quality and lead time: A well-planned and optimized output will convert raw materials into finished goods. This will equal shorter overall lead times, increased profit margins, and higher customer satisfaction.

Production Scheduling Methods

There are a few scheduling techniques to handle the process better. We will take a look at how they work.

Infinite Capacity Planning

It assumes that there aren't limitations to work resources and there is sufficient capacity for workstations and workforce available to finish all planned jobs.

This will work when dealing with a few relatively larger manufacturing projects at once, and there is no threat of overloading your production quantities over the workstations.

Finite Capacity Planning

On the other hand, Finite capacity planning considers the limits of the resources needed for production.

This method will work well when many jobs with complex routing are scheduled on different workstations, increasing the risk of developing bottlenecks on the manufacturing schedule. When there is insufficient resource capacity, the work can be scheduled on the next available slot if there is enough material available to start.

Forward Scheduling

In forward scheduling, the earliest starting time will be decided for each production run. Then, operations are scheduled, moving forward from the first operation to the last one, going on one by one. It is useful for make-to-stock setups for the managers who wish to pack their schedules as tight as possible.

Backward Scheduling

It starts by issuing a due date and setting when operations must be finished for each job. These operations are scheduled to move backward in time and will start to form the last operation until the first, going one by one.

It becomes useful when working with strict due dates and the just-in-time methodology to minimize progress and the overall standing inventory.

Stages of the Production Scheduling Process

Successfully implementing production schedules to help companies to organize many complex processes will involve the following six steps.

Planning

It is the very first stage when creating a production schedule. Production schedulers will determine a production goal and analyze the necessary resources.

There are two ways of planning that professionals will consider:

- Dynamic Planning: It assumes that changes to the schedule will occur before reaching the production goal.

- Static Planning: It assumes that all stages of production will adhere to the schedule without changes.

Consider which type of planning will be more optimal for your business process.

Routing

Professionals will often develop steps that outline how their company transports its finished products to the consumer market. Then they analyze the best ways to transition raw materials into the final product.

The main objective of this stage is to discover the most cost-effective method from procurement to production completion.

Scheduling

This process establishes the time frame for completing every stage of production. It states the final deadline to finish the entire project.

Scheduling can fall into three different categories:

- Master Production Schedule: The master schedule is a plan to manufacture a product within a certain time frame. It will include components such as budget, personnel, resources, and routing processes.

- Manufacturing Schedule: It is a plan for production that only includes the steps required to convert raw materials into finished products.

- Retail Operations Schedule: It is similar to a master production schedule, but it concerns products designed for retailers.

Dispatching

It entails implementing all the processes that schedulers have prepared. They ensure that all resources are available to begin production.

Schedulers also issue instructions to personnel that is involved in the production process, so they can understand their roles and responsibilities within the production schedule.

Execution

It is the final step of the production scheduling process. It is the realization of schedulers’ plans.

They will make sure that all the processes operate efficiently and that production finishes within the pre-established time frame. This will ensure that each customer receives their order efficiently and promptly.

Maintenance

Updating and monitoring the schedule throughout the production process will help managers ensure that the plan is continuously up to date.

It is also important to share these changes in the schedule with everyone involved, so every team member is aware of the plan and its expectations.

How to Optimize Production Scheduling

There are many strategies for optimizing the production scheduling process, but making agile scheduling ultimately trumps everyone else.

To achieve such a goal, you should:

- Build a dynamic schedule so you can adjust quickly when something goes wrong. That could mean redistributing resources, understanding worker capacity, and contacting reinforcements if needed.

- Control what is actually on WIP (work-in-progress), reserving this label for jobs that have to be done immediately. If everything is on WIP, then nothing has priority.

- Prioritize based on on-time delivery and not based on scheduled due dates.

Free Production Schedule Templates for Excel and Word

Now, let's make your very own production schedule for your business. You don't need to worry. We understand that starting one from scratch could impose a daunting task for some and that you might be in a hurry to sit down and search for how to do it properly.

That's why we brought you a few production schedule templates that you can adjust to fit your needs. All that you need to do is have Microsoft Excel or Word installed on your PC, which comes in handy as these templates are easy to understand and modify.

And if you need an Excel or Word CD key, you can grab one at the RoyalCDKeys store for a low price. This will include the mentioned programs and the latest version of Office. The whole package includes software like Microsoft PowerPoint, Access, Outlook, and more.

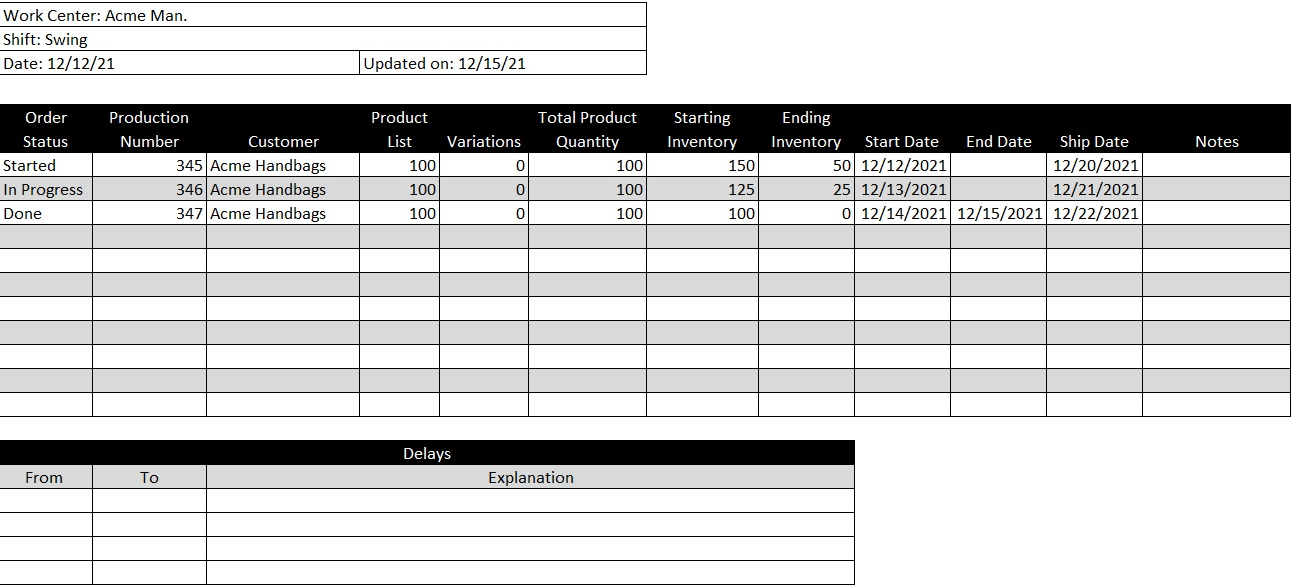

Master Production Schedule Template

This production schedule template will help managers put all the pieces of their manufacturing schedule together efficiently and quickly.

You will find fields to note the order status, product quantity and variations, starting and ending inventory, the ship date, and much more.

You can download this free template as an Excel spreadsheet from the Project Manager website.

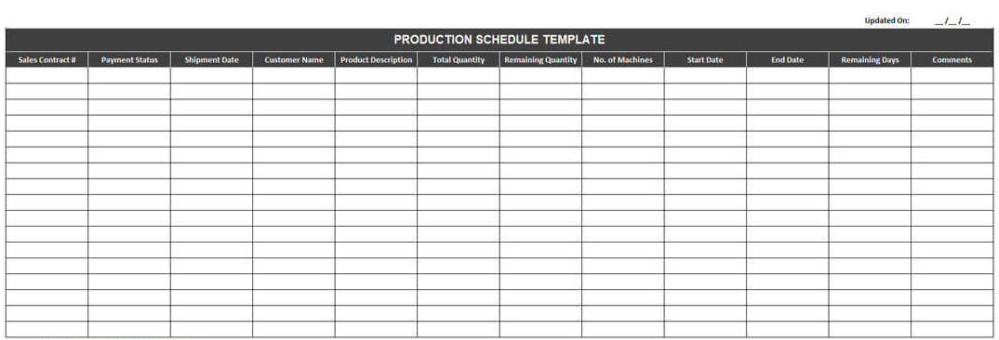

Production Schedule Template

This template contains a large variety of items to fill in, which includes sales contact number, product description, customer name, payment status, total quantity, delivery date, remaining quantity, both start, and end date, number of machines, days left, and an additional field for comments and notes.

You can download this template for Excel from TemplatesFreeDownload.com.

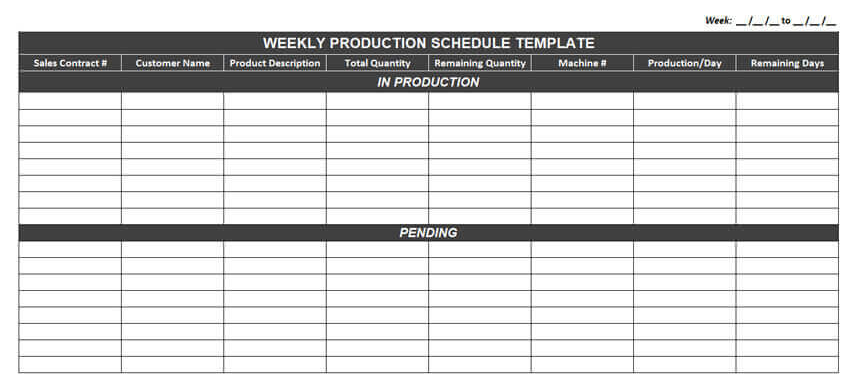

Weekly Production Schedule Template

The weekly production schedule templates are most relevant to production floor use. This will include information on the production go-ahead from the planning team.

With this data, the production team can see the completion of any order and check the resources for the next one. They can also plan to set the production line for new orders. They will monitor it daily to achieve production goals and manage changes.

You can download it from the TemplatesFreeDownload website, too.

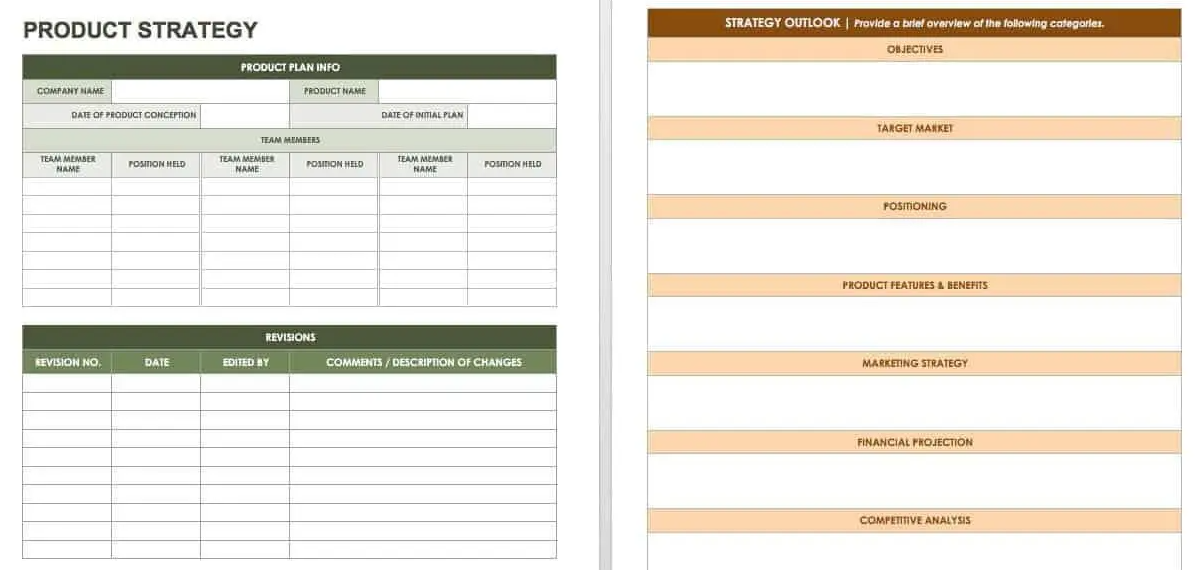

Product Strategy Template

This template will complement fine with the previous ones. You can create a comprehensive plan summarizing your strategy and vision for each product, including key information on goals, target customers, marketing, scheduling, sales strategy, and more.

This strategic template will provide managers with a detailed report that covers background information while the action steps in.

You can download this template as a Word document from Smartsheet.com.

Product Positioning Template

Use this template to define product positioning by analyzing your target market. It will allow you to identify the problems your product solves. If you are targeting more than one customer segment, you might need to do it many times for one product.

You can also download this Word file from the Smartsheet website.

Key Takeaways

Production scheduling is not a simple task, as many people and tasks happen simultaneously. Then you have to add the chaotic nature of how things could suffer changes during the production process, which could change your projected demand planning.

So, that's why you need to have everything well-organized and prepared for any sudden change. With everything we wrote in this article, plus the templates offered above, you will be able to better organize your company and be ahead of any obstacle that might appear on the road for your business.